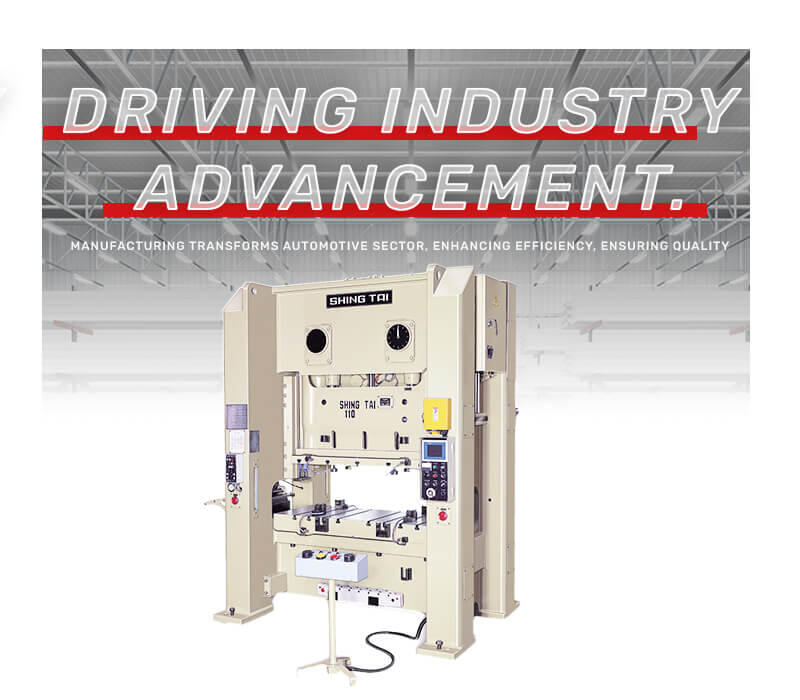

Wet Clutch and Brake

High transmission wet clutch / brake

- High performance and efficiency oil bathed clutch / brake lining provide lasting service life time, without the worry of being worn out.

- Low inertia / High torque multi-disk design, ensuring more improved sensitivity on start and brake.

- Unique design allows faster intermitten operation, good for synchronized operation with robot arm.

- Low noise, zero pollution, fully complied to the future requirement of environment protection.

Slide guide structure

- The square copper liner and lubrication system keeps the slide in very high precision.

- Slide side thrust to be sustained direct by frame.

- The slide liner is made of phosphor bronze, being smooth and easy to keep precision. Prolong die life and elevation the high quality of the products.

Hydraulic overload protection system

- When the press is operating under overloading, the oil escapes throung the metal seal and the press is brought to a stop instantly.

- It's function is to make instant emergent stop when the press is operating under overloading (It's inductive reaction is within 1/100 sec.) At this time, The press shoule be turned to the upper dead center and will return to normal operating after the overloading is relieved.

Structural design

It is smaller in size than the conventional press, but more effective in space occupation.

Angular deflection

The frame steel plate has high-tensile stress and minimal angular deflection.

This feature to reduce punching deformation maintains precise punching position, and prolongs the life of the dies.

| SC1-25 | ||||||

|---|---|---|---|---|---|---|

| Model | (S) | (1) | (2) | |||

| Capacity | ton | 25 | ||||

| Tonnage rating point (above B.D.C.) | mm | 2.3 | 2.5 | |||

| Stroke length | mm | 30 | 50 | 80 | ||

| Stroke per minute | Standard | spm | 90 | 120 | ||

| Variable | 90 ~ 220 | 60 ~ 140 | 60 ~ 120 | |||

| Allowable intermittent | spm | 48 | 74 | |||

| Die height, slide to bolster | mm | 200 | 220 | |||

| Slide adjustment | mm | 50 | ||||

| Slide area (a1xb1) | mm | 350 × 250 | ||||

| Bolster area (a2xb3) | mm | 700 × 320 | ||||

| Bolster thickness | mm | 85 | ||||

| Frame gap (b2) | mm | 170 | ||||

| Frame inside measurement (a3) | mm | 420 | ||||

| Bolster surfane height h1 | mm | 780 | ||||

| Press overall height h2 | mm | 1935 | 1980 | |||

| Position of anchor bolt (a4xb4) | mm | 650 × 920 | ||||

| Floor space required (a5xb5) | mm | 740 × 1070 | ||||

| Max. measurement of press (a6xb6) | mm | 905× 1280 | ||||

| Nominal working energy | kg-m | 65 | ||||

| Main motor | Hp x p | 3 × 4 | ||||

| Required air pressure | kg/c㎡ | 5 | ||||

| Approx. machine weight | mt | 2 | ||||

| SC1-35 | ||||||

|---|---|---|---|---|---|---|

| Model | (S) | (1) | (2) | |||

| Capacity | ton | 35 | ||||

| Tonnage rating point (above B.D.C.) | mm | 2.3 | 2.6 | |||

| Stroke length | mm | 50 | 80 | 110 | ||

| Stroke per minute | Standard | spm | 90 | 100 | ||

| Variable | 90 ~ 200 | 70 ~ 130 | 60 ~ 110 | |||

| Allowable intermittent | spm | 48 | 65 | |||

| Die height, slide to bolster | mm | 220 | 250 | |||

| Slide adjustment | mm | 55 | ||||

| Slide area (a1xb1) | mm | 400 × 300 | ||||

| Bolster area (a2xb3) | mm | 780 × 400 | ||||

| Bolster thickness | mm | 100 | ||||

| Frame gap (b3xh3) | mm | 210 | ||||

| Frame inside measurement a3 | mm | 480 | ||||

| Bolster surfane height h1 | mm | 800 | ||||

| Press overall height h2 | mm | 2135 | 2180 | |||

| Position of anchor bolt (a4xb4) | mm | 730 × 1000 | ||||

| Floor space required (a5xb5) | mm | 830 × 1170 | ||||

| Max. measurement of press (a6xb6) | mm | 990× 1380 | ||||

| Nominal working energy | kg-m | 91 | ||||

| Main motor | Hp x p | 5 × 4 | ||||

| Required air pressure | kg/c㎡ | 5 | ||||

| Approx. machine weight | mt | 2.8 | ||||

| SC1-45 | ||||||

|---|---|---|---|---|---|---|

| Model | (S) | (1) | (2) | |||

| Capacity | ton | 45 | ||||

| Tonnage rating point (above B.D.C.) | mm | 2.3 | 3.2 | |||

| Stroke length | mm | 50 | 80 | 120 | ||

| Stroke per minute | Standard | spm | 80 | 100 | 80 | |

| Variable | 85 ~ 180 | 60 ~ 105 | 50 ~ 95 | |||

| Allowable intermittent | spm | 49 | 51 | 58 | ||

| Die height, slide to bolster | mm | 250 | 270 | |||

| Slide adjustment | mm | 60 | ||||

| Slide area (a1xb1) | mm | 430 × 340 | ||||

| Bolster area (a2xb3) | mm | 830 × 440 | ||||

| Bolster thickness | mm | 110 | ||||

| Frame gap (b3xh3) | mm | 230 | ||||

| Frame inside measurement a3 | mm | 520 | ||||

| Bolster surfane height h1 | mm | 800 | ||||

| Press overall height h2 | mm | 2260 | 2300 | |||

| Position of anchor bolt (a4xb4) | mm | 750 × 1100 | ||||

| Floor space required (a5xb5) | mm | 830 × 1260 | ||||

| Max. measurement of press (a6xb6) | mm | 1010× 1470 | ||||

| Nominal working energy | kg-m | 144 | ||||

| Main motor | Hp x p | 5 × 4 | ||||

| Required air pressure | kg/c㎡ | 5 | ||||

| Approx. machine weight | mt | 3.8 | ||||

| SC1-60 | ||||||

|---|---|---|---|---|---|---|

| Model | (S) | (1) | (2) | |||

| Capacity | ton | 60 | ||||

| Tonnage rating point (above B.D.C.) | mm | 2.3 | 4 | |||

| Stroke length | mm | 55 | 90 | 140 | ||

| Stroke per minute | Standard | spm | 70 | 90 | 70 | |

| Variable | 80 ~ 165 | 55 ~ 100 | 45 ~ 85 | |||

| Allowable intermittent | spm | 50 | 45 | 50 | ||

| Die height, slide to bolster | mm | 270 | 300 | |||

| Slide adjustment | mm | 70 | ||||

| Slide area (a1xb1) | mm | 480 × 400 | ||||

| Bolster area (a2xb3) | mm | 900 × 520 | ||||

| Bolster thickness | mm | 130 | ||||

| Frame gap (b3xh3) | mm | 270 | ||||

| Frame inside measurement a3 | mm | 580 | ||||

| Bolster surfane height h1 | mm | 900 | ||||

| Press overall height h2 | mm | 2520 | 2575 | |||

| Position of anchor bolt (a4xb4) | mm | 860 × 1135 | ||||

| Floor space required (a5xb5) | mm | 960 × 1400 | ||||

| Max. measurement of press (a6xb6) | mm | 1110× 1610 | ||||

| Nominal working energy | kg-m | 240 | ||||

| Main motor | Hp x p | 7.5 × 4 | ||||

| Required air pressure | kg/c㎡ | 5 | ||||

| Approx. machine weight | mt | 6 | ||||

| SC1-80 | ||||||

|---|---|---|---|---|---|---|

| Model | (S) | (1) | (2) | |||

| Capacity | ton | 80 | ||||

| Tonnage rating point (above B.D.C.) | mm | 3.2 | 5 | |||

| Stroke length | mm | 60 | 100 | 160 | ||

| Stroke per minute | Standard | spm | - | - | 60 | |

| Variable | 75 ~ 150 | 50 ~ 110 | 40 ~ 75 | |||

| Allowable intermittent | spm | 60 | 53 | 60 | ||

| Die height, slide to bolster | mm | 300 | 320 | |||

| Slide adjustment | mm | 80 | ||||

| Slide area (a1xb1) | mm | 540 × 460 | ||||

| Bolster area (a2xb3) | mm | 980 × 600 | ||||

| Bolster thickness | mm | 140 | ||||

| Frame gap (b2) | mm | 310 | ||||

| Frame inside measurement a3 | mm | 640 | ||||

| Bolster surfane height h1 | mm | 900 | ||||

| Press overall height h2 | mm | 2685 | 2735 | |||

| Position of anchor bolt (a4xb4) | mm | 920 × 1310 | ||||

| Floor space required (a5xb5) | mm | 1040 × 1550 | ||||

| Nominal working energy | kg-m | 400 | ||||

| Main motor | Hp x p | 10 × 4 | ||||

| Required air pressure | kg/c㎡ | 5 | ||||

| Approx. machine weight | mt | 8 | ||||

| SC1-110 | ||||||

|---|---|---|---|---|---|---|

| Model | (S) | (1) | (2) | |||

| Capacity | ton | 110 | ||||

| Tonnage rating point (above B.D.C.) | mm | 3.2 | 5 | |||

| Stroke length | mm | 70 | 110 | 180 | ||

| Stroke per minute | Standard | spm | - | - | 50 | |

| Variable | 65 ~ 135 | 45 ~ 100 | 35 ~ 65 | |||

| Allowable intermittent | spm | 50 | 48 | 50 | ||

| Die height, slide to bolster | mm | 320 | 350 | |||

| Slide adjustment | mm | 90 | ||||

| Slide area (a1xb1) | mm | 625 × 520 | ||||

| Bolster area (a2xb3) | mm | 1170 × 680 | ||||

| Bolster thickness | mm | 150 | ||||

| Frame gap (b2) | mm | 350 | ||||

| Frame inside measurement a3 | mm | 670 | ||||

| Bolster surfane height h1 | mm | 900 | ||||

| Press overall height h2 | mm | 2885 | 2950 | |||

| Position of anchor bolt (a4xb4) | mm | 1040 × 1510 | ||||

| Floor space required (a5xb5) | mm | 1140 × 1760 | ||||

| Nominal working energy | kg-m | 550 | ||||

| Main motor | Hp x p | 15 × 4 | ||||

| Required air pressure | kg/c㎡ | 5 | ||||

| Approx. machine weight | mt | 11 | ||||

| SC1-160 | ||||||

|---|---|---|---|---|---|---|

| Model | (S) | (1) | (2) | |||

| Capacity | ton | 160 | ||||

| Tonnage rating point (above B.D.C.) | mm | 4 | 6 | |||

| Stroke length | mm | 80 | 130 | 200 | ||

| Stroke per minute | Standard | spm | - | - | 45 | |

| Variable | 55 ~ 115 | 40 ~ 85 | 30 ~ 55 | |||

| Allowable intermittent | spm | 23 | 29 | 38 | ||

| Die height, slide to bolster | mm | 350 | 400 | |||

| Slide adjustment | mm | 100 | ||||

| Slide area (a1xb1) | mm | 700 × 580 | ||||

| Bolster area (a2xb3) | mm | 1220 × 760 | ||||

| Bolster thickness | mm | 165 | ||||

| Frame gap (b2) | mm | 390 | ||||

| Frame inside measurement a3 | mm | 740 | ||||

| Bolster surfane height h1 | mm | 900 | ||||

| Press overall height h2 | mm | 3115 | 3200 | |||

| Position of anchor bolt (a4xb4) | mm | 1140 × 1790 | ||||

| Floor space required (a5xb5) | mm | 1240 × 2030 | ||||

| Nominal working energy | kg-m | 960 | ||||

| Main motor | Hp x p | 20 × 4 | ||||

| Required air pressure | kg/c㎡ | 5 | ||||

| Approx. machine weight | mt | 16 | ||||

| SC1-200 | ||||||

|---|---|---|---|---|---|---|

| Model | (S) | (1) | (2) | |||

| Capacity | ton | 200 | ||||

| Tonnage rating point (above B.D.C.) | mm | 4 | 6 | |||

| Stroke length | mm | 95 | 160 | 250 | ||

| Stroke per minute | Standard | spm | - | - | 35 | |

| Variable | 45 ~ 95 | 30 ~ 70 | 25 ~ 45 | |||

| Allowable intermittent | spm | 39 | 37 | 35 | ||

| Die height, slide to bolster | mm | 410 | 450 | |||

| Slide adjustment | mm | 110 | ||||

| Slide area (a1xb1) | mm | 880 × 650 | ||||

| Bolster area (a2xb3) | mm | 1440 × 840 | ||||

| Bolster thickness | mm | 180 | ||||

| Frame gap (b2) | mm | 430 | ||||

| Frame inside measurement a3 | mm | 940 | ||||

| Bolster surfane height h1 | mm | 1000 | ||||

| Press overall height h2 | mm | 3605 | 3690 | |||

| Position of anchor bolt (a4xb4) | mm | 1360 × 2020 | ||||

| Floor space required (a5xb5) | mm | 1460 × 2290 | ||||

| Nominal working energy | kg-m | 1200 | ||||

| Main motor | Hp x p | 25 × 4 | ||||

| Required air pressure | kg/c㎡ | 5 | ||||

| Approx. machine weight | mt | 23 | ||||

| SC1-250 | ||||

|---|---|---|---|---|

| Model | (1) | (2) | ||

| Capacity | ton | 250 | ||

| Tonnage rating point (above B.D.C.) | mm | 7 | ||

| Stroke length | mm | 170 | 280 | |

| Stroke per minute | Standard | spm | - | 25 |

| Variable | 25 ~ 45 | 20 ~ 35 | ||

| Allowable intermittent | spm | 32 | 28 | |

| Die height, slide to bolster | mm | 450 | 550 | |

| Slide adjustment | mm | 120 | ||

| Slide area (a1xb1) | mm | 950 × 720 | ||

| Bolster area (a2xb3) | mm | 1550 × 920 | ||

| Bolster thickness | mm | 190 | ||

| Frame gap (b2) | mm | 470 | ||

| Frame inside measurement a3 | mm | 980 | ||

| Bolster surfane height h1 | mm | 1100 | ||

| Press overall height h2 | mm | 4015 | 4170 | |

| Position of anchor bolt (a4xb4) | mm | 1440 × 2000 | ||

| Floor space required (a5xb5) | mm | 1560 × 2400 | ||

| Nominal working energy | kg-m | 1400 | ||

| Main motor | Hp x p | 30 × 4 | ||

| Required air pressure | kg/c㎡ | 5 | ||

| Approx. machine weight | mt | 30 | ||