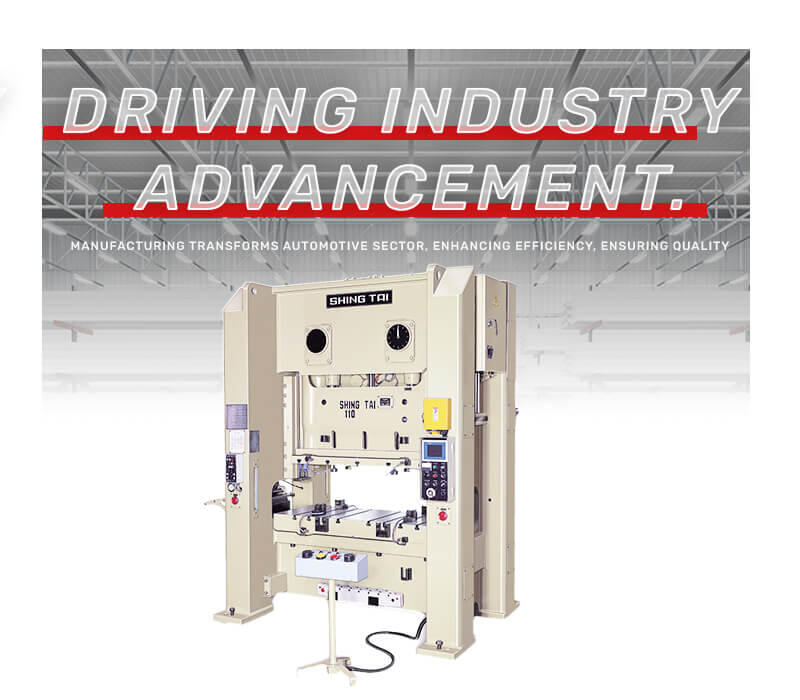

Zero clearance precision guide

Designed With 8-face needle roller bearing guide, and programmed pressure to ensure slide's horizontal and vertical precision when moving back and forth zero clearance on the guide .

Unique crank design

The crank is supported by both bushing and needle roller bearing that offers the advantage of reducing friction and increasing weight load capacity, enabling smooth press operation and serviceability.

Rigid cast frame

Rigid cast frame has the advantages of low oscillation, good shock absorbency, low coefficient of expansion and long time operation stability.

Double post guide removal of lateral pressure

The double post guide function to channel the lateral pressure produced in the process of stamping to reduce damages to die , and maintain the slide's axial up and down motion , which in turn protects die and enhances product quality.

Die height adjustment

Adjustment is controlled by a hydraulic lock device for product precision and consistency.

Dynamic balance device

The dynamic balancer can effectively counter press vibration to protect die and product as well as maintain precision and quality.

Computer control system

The company control monitor the rotation, output, deviation and they are showed on the control panel. The user can realize every massage from panel and troubleshooting.

Circulating cooling device

Under hi-speed operation, machine parts are heated from friction that can cause thermal displacement, and affect product precision. This series is equipped with circulating cooling system for effective control of thermal displacement.

| KD-30F | |||

|---|---|---|---|

| Capacity | ton | 30 | |

| Stroke leight | mm | 25 | 30 |

| Stroke per minute | spm | 300 ~ 1000 | 300 ~ 900 |

| Die height | mm | 257 | 250 |

| Slide adjustment | mm | 30 | |

| Slide area | mm | 560 x 300 | |

| Bolster area | mm | 600 x 450 x 90 | |

| Bed opening | mm | 460 x 160 | |

| Side opneing | mm | 200 | |

| Motor | HP x P | 10 x 4 | |

| Lubrication system | Circulating automated lubrication | ||

| KD-45F | ||||

|---|---|---|---|---|

| Capacity | ton | 45 | ||

| Stroke leight | mm | 30 | 40 | |

| Stroke per minute | spm | 150 ~ 900 | 150 ~ 600 | |

| Die height | mm | 265 | 260 | |

| Slide adjustment | mm | 40 | ||

| Slide area | mm | 600 x 340 | ||

| Bolster area | mm | 700 x 500 x 100 | ||

| Bed opening | mm | 540 x 180 | ||

| Side opneing | mm | 300 | ||

| Motor | HP x P | 15 x 4 | ||

| Lubrication system | Circulating automated lubrication | |||

| KD-60F | ||||

|---|---|---|---|---|

| Capacity | ton | 60 | ||

| Stroke leight | mm | 30 | 40 | 60 |

| Stroke per minute | spm | 150 ~ 800 | 150 ~ 500 | 150 ~ 400 |

| Die height | mm | 305 | 300 | 290 |

| Slide area | mm | 900 x 500 | ||

| Bolster area | mm | 950 x 600 x 120 | ||

| Bed opening | mm | 750 x 200 | ||

| Side opneing | mm | 300 | ||

| Motor | HP x P | 20 x 4 | ||

| Lubrication system | Circulating automated lubrication | |||

| KD-80F | ||||

|---|---|---|---|---|

| Capacity | ton | 80 | ||

| Stroke leight | mm | 30 | 50 | 75 |

| Stroke per minute | spm | 150 ~ 700 | 150 ~ 500 | 100 ~ 300 |

| Die height | mm | 360 | 350 | 338 |

| Slide adjustment | mm | 50 | ||

| Slide area | mm | 1100 x 540 | ||

| Bolster area | mm | 1100 x 800 x 130 | ||

| Bed opening | mm | 900 x 260 | ||

| Side opneing | mm | 300 | ||

| Motor | HP x P | 30 x 4 | ||

| Lubrication system | Circulating automated lubrication | |||