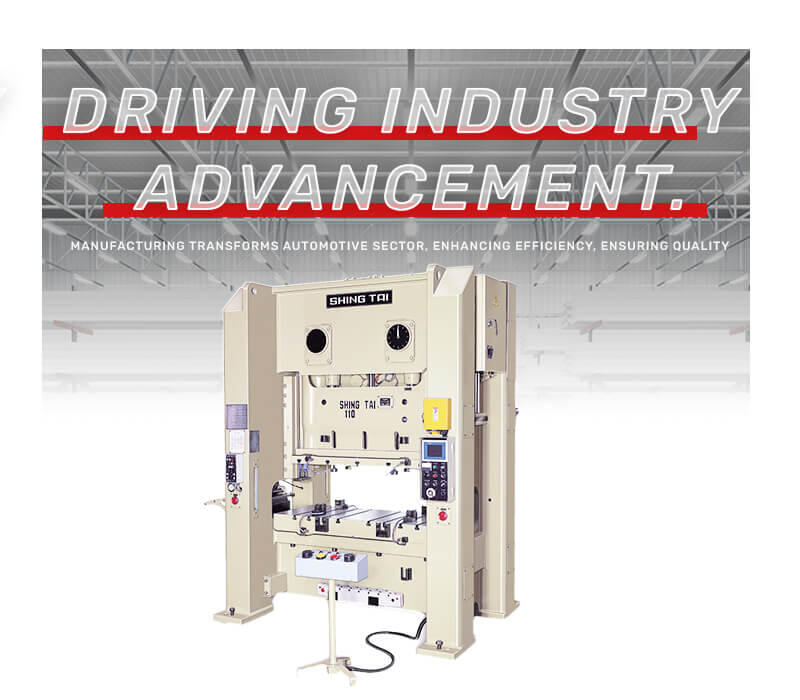

The Design Without Opening is a realization of high dimensional precision and productivity

Rigid frame structural design provides ultra accuracy and increases productivity.

The rigid, unitized steel frame provides a solid base to resist deflection and ensures accurate stampings and longer dies lifespan. With the fine designed mechanism and structure reallocation, it not only reduces installation space but also prevents the deformation.Brand new slide guide design

The slide guide is located in the center of the slide block in front and rear directions. The press enhances the front/rear and left/right centrifugal loads and dynamic precision within range of the slide block in motion. It also prolongs the life span of the mold.

Forced oil lubrication system

Forced, automated oil lubrication system on the crank bearings and in slide guide area enhances the operation; restrains the frame deformation and fulfills the demand of precise processing.

Eco-friendly design

By utilizing the rigid fabricated steel framing and the inverter motor, this series successfully reduces undesirable noise and vibration, and requires less energy. As well, the forced oil lubrication system substantially decreases the oil consumption and therefore it generates less waste oil and improves the working environment.

Increased Slide Right-Left dimension

In response to production requirements to increase the number of operation, the enlarged slide area can accommodate larger tooling to work more efficiently and more accurately.

Large, easy-to-use touchscreen display.

The control panel with a large touchscreen allows easy access to setup functions and is easy to use. Extra functions can be customized and specified to meet customer requirements and promote the efficiency of production and management.

| LH1-80 | ||||||

|---|---|---|---|---|---|---|

| Model | (S) | (1) | (1LL) | (2) | (2LL) | |

| style | Crank | Crank | Link | Crank | Link | |

| Capacity | ton | 80 | ||||

| Tonnage rating point | mm | 3.2 | 5 | 5 | 5 | 5 |

| Stroke length | mm | 60 | 100 | 100 | 160 | 160 |

| Stroke per minute | spm | 75~150 | 55~125 | 55~110 | 40~80 | 40~75 |

| Die height | mm | 300 | 320 | |||

| Silde adjustment | mm | 80 | ||||

| Slide area (LR x FB) | mm | 700 x 460 | ||||

| Bolster area (LR x FB | mm | 900 x 460 | 900 x 600 | |||

| Side open | mm | 300 x 270 (220) | 440 x 300 (250) | |||

| Bolster thickness | mm | 140 | ||||

| Main motor | HP*P | 10HP*4P | ||||

| Required air pressure | kg/cm2 | 5 | ||||

| LH1-110 | ||||||

|---|---|---|---|---|---|---|

| Model | (S) | (1) | (1LL) | (2) | (2LL) | |

| style | Crank | Crank | Link | Crank | Link | |

| Capacity | ton | 110 | ||||

| Tonnage rating point | mm | 3.2 | 5 | 5 | 5 | 5 |

| Stroke length | mm | 70 | 110 | 110 | 180 | 180 |

| Stroke per minute | spm | 65~135 | 50~110 | 50~100 | 35~70 | 35~65 |

| Die height | mm | 320 | 350 | |||

| Silde adjustment | mm | 90 | ||||

| Slide area (LR x FB) | mm | 800 x 520 | ||||

| Bolster area (LR x FB | mm | 1000 x 520 | 1100 x 680 | |||

| Side open | mm | 340 x 270 (250) | 500 x 300 (280) | |||

| Bolster thickness | mm | 155 | ||||

| Main motor | HP*P | 15HP*4P | ||||

| Required air pressure | kg/cm2 | 5 | ||||

| LH1-160 | ||||||

|---|---|---|---|---|---|---|

| Model | (S) | (1) | (1LL) | (2) | (2LL) | |

| style | Crank | Crank | Link | Crank | Link | |

| Capacity | ton | 160 | ||||

| Tonnage rating point | mm | 4 | 6 | 6 | 6 | 6 |

| Stroke length | mm | 80 | 130 | 130 | 200 | 200 |

| Stroke per minute | spm | 55~115 | 40~95 | 40~85 | 30~60 | 30~55 |

| Die height | mm | 350 | 400 | |||

| Silde adjustment | mm | 100 | ||||

| Slide area (LR x FB) | mm | 900 x 580 | ||||

| Bolster area (LR x FB | mm | 1150 x 600 | 1150 x 760 | |||

| Side open | mm | 380 x 330 (280) | 560 x 380 (330) | |||

| Bolster thickness | mm | 165 | ||||

| Main motor | HP*P | 15HP*4P | ||||

| Required air pressure | kg/cm2 | 5 | ||||

| LH1-200 | ||||||

|---|---|---|---|---|---|---|

| Model | (S) | (1) | (1LL) | (2) | (2LL) | |

| style | Crank | Crank | Link | Crank | Link | |

| Capacity | ton | 200 | ||||

| Tonnage rating point | mm | 4 | 6 | 6 | 6 | 6 |

| Stroke length | mm | 95 | 160 | 160 | 250 | 250 |

| Stroke per minute | spm | 45~95 | 35~80 | 35~70 | 25~50 | 25~45 |

| Die height | mm | 410 | 450 | |||

| Silde adjustment | mm | 110 | ||||

| Slide area (LR x FB) | mm | 1000 x 650 | ||||

| Bolster area (LR x FB | mm | 1250 x 680 | 1250 x 840 | |||

| Side open | mm | 420 x 380 (330) | 620 x 420 (370) | |||

| Bolster thickness | mm | 180 | ||||

| Main motor | HP*P | 20HP*4P | ||||

| Required air pressure | kg/cm2 | 5 | ||||